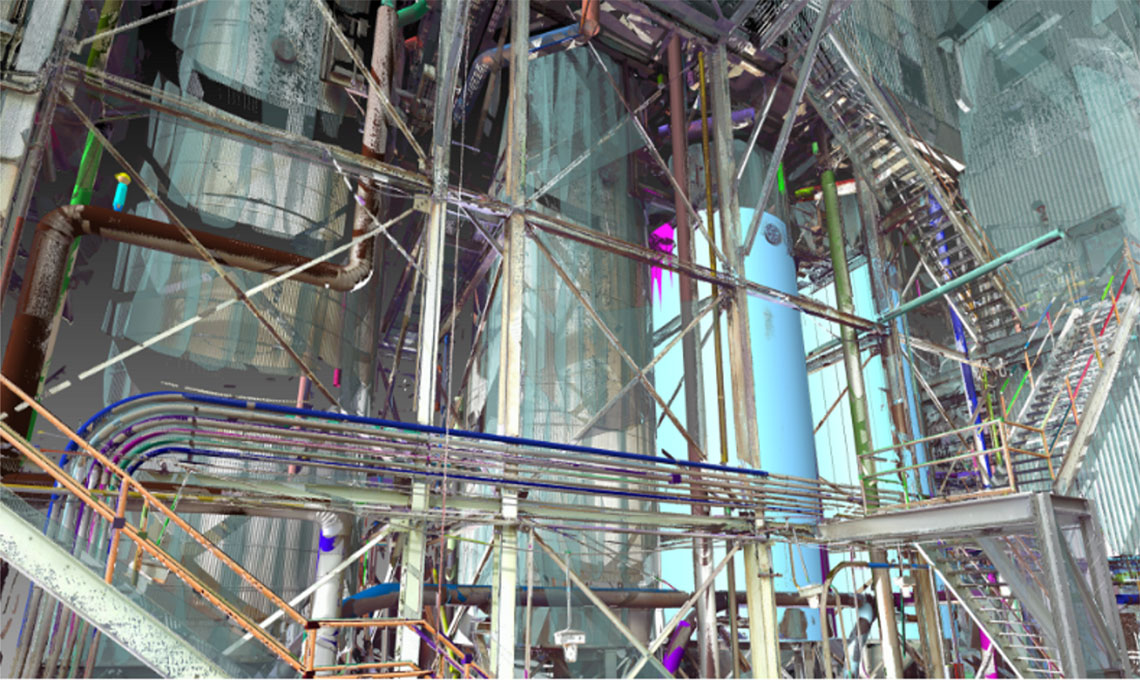

Whether owners want to or not, Their Industrial units and factories are naturally subjected to various engineering changes over operational time. From small changes for easier access to different parts while operation. To repairing different mechanical, electrical, utility systems. Each of these small changes that occurs over time may not be that important. But when we have to get in a new project inside those area, we have to consider all of them together to see what we have to deal with. They create interactions in the workplace that are virtually impossible to record. The combination of these not recorded modifications over time can bring the system into greater engineering and economic challenges.

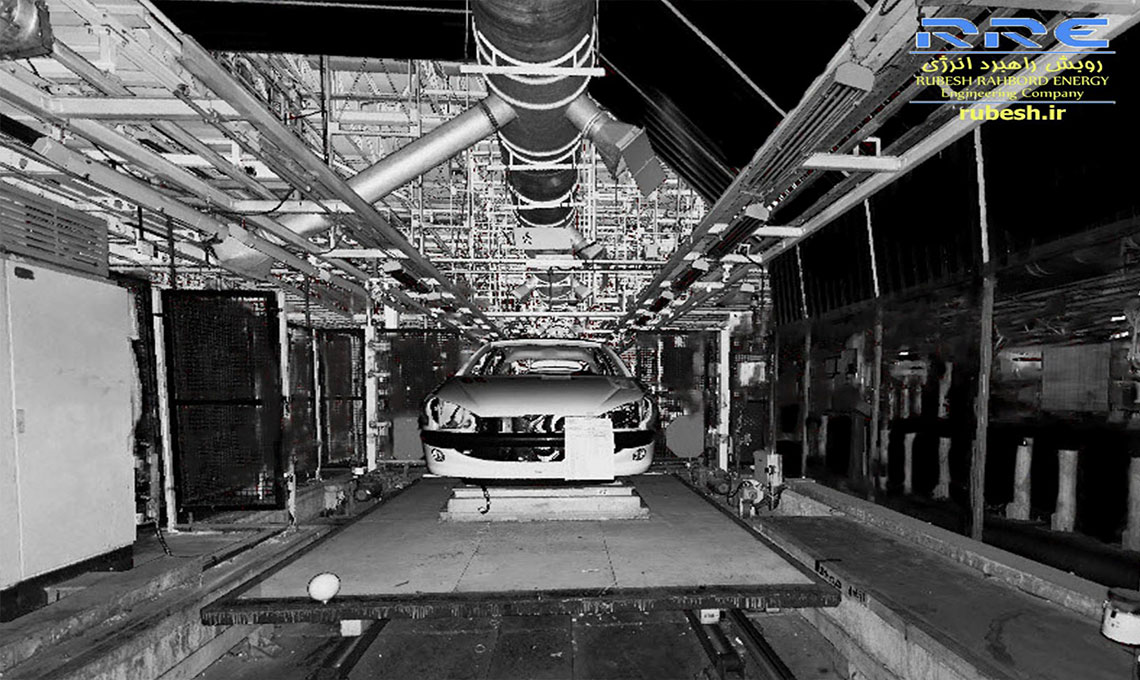

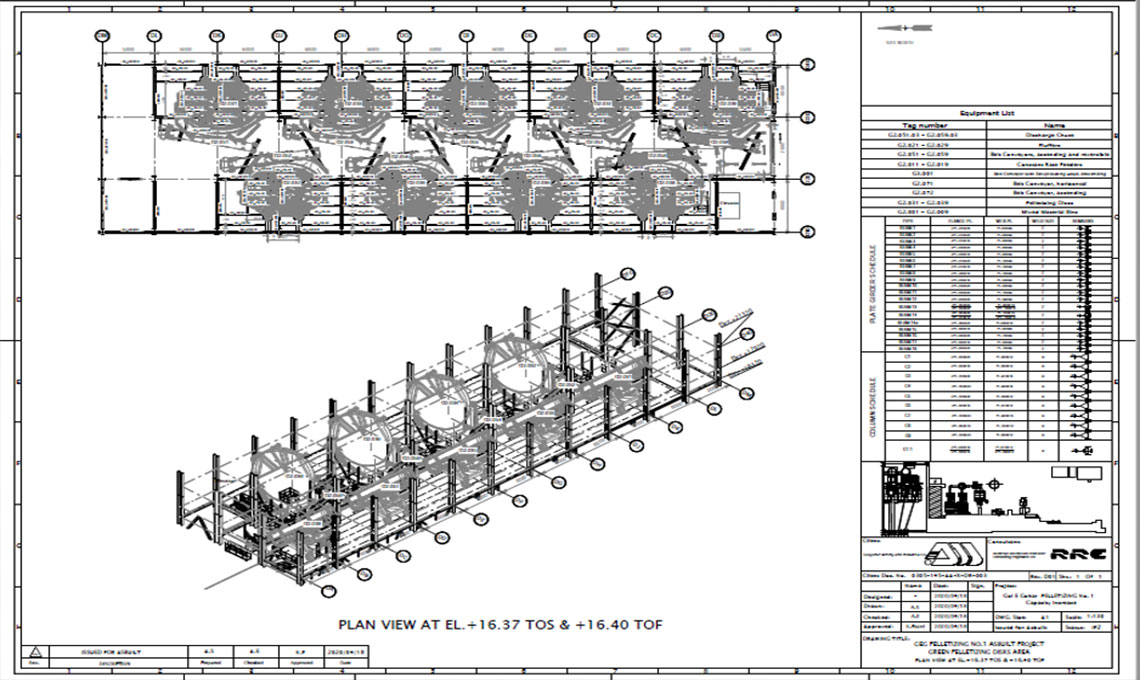

Production units like cement / copper / mining industries, Steel / car / iron / dairy factories..., needs to be continues renovated. Under a definite time table every single system like a rotary equipment, smelting furnaces and material transmission systems or whole of the production system need to be overhauled or partially reconstructed. The construction of a new steel structure or a single platform among the other existing items like buildings, beams and columns ... is something that always happens. Sometimes whole of the production system or some parts of them should be replaced. Normally, we face with different alternatives to decide. So, we need to run a developed feasibility study to create the best engineering solution.

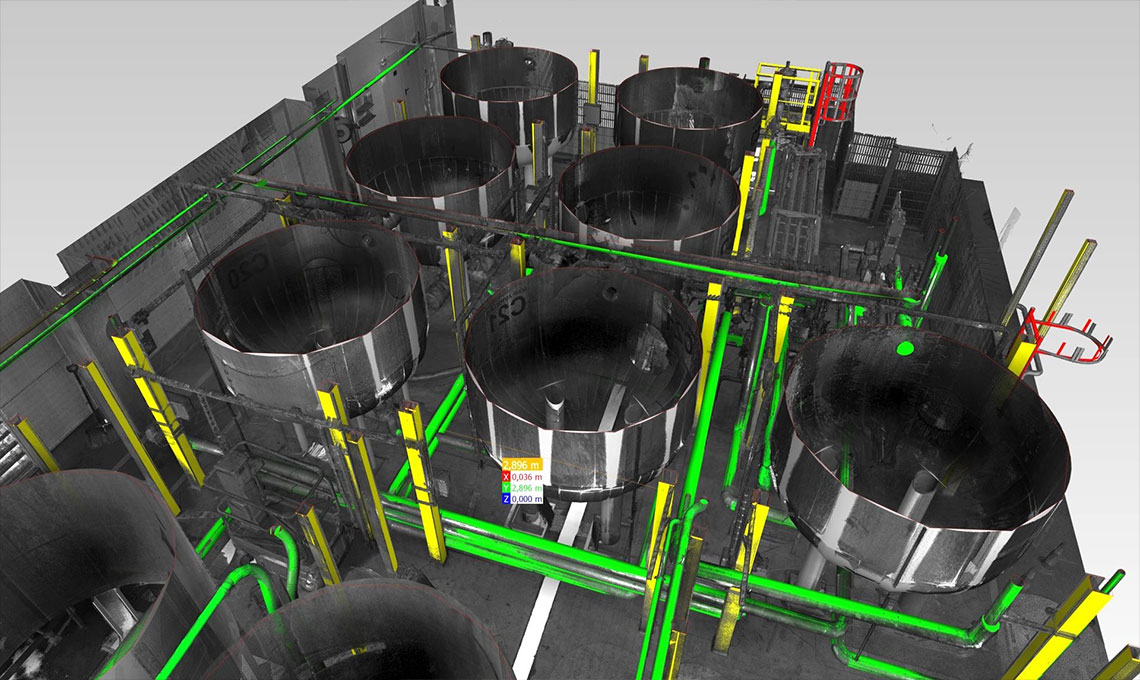

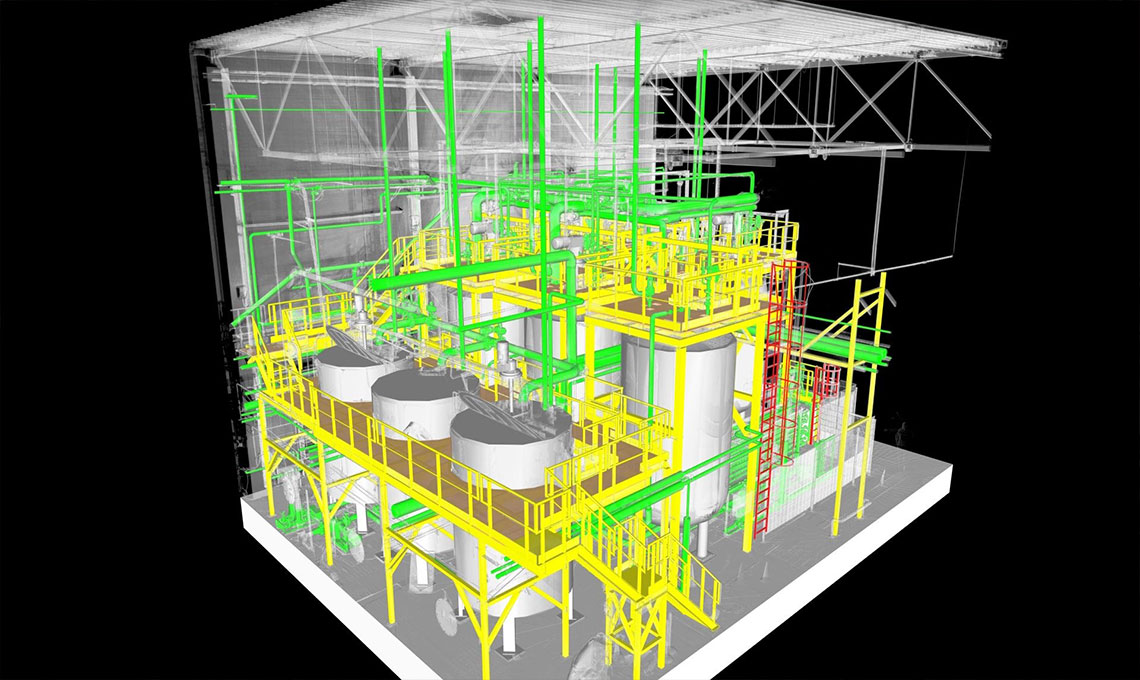

All of these detail engineering decisions have to be evolved under the shadow of three influential aspects of cost, time and efficiency. It is quite rational that we face with the most appropriate engineering decisions by utilizing 3D laser scanning technology in industrial areas.