Process units such as refineries, petrochemicals, power plants, various types of process factories, etc. have many physical complexities in their operating area. Advancing design and engineering goals in these units is very challenging. Many of them were built in the years that computer systems were not existed and execution plans were prepared without any IT devices. Engineering archived documents naturally disperse over time and lose their effectiveness. Usually, after a while, what remains to decide about the running engineering project goals does not have the necessary coherence and requires multiple updates. Archived documents which have been inherited from starting day, creates a lot of problems when it comes to checking their conformity with existing situation. But this is not the whole of the story!

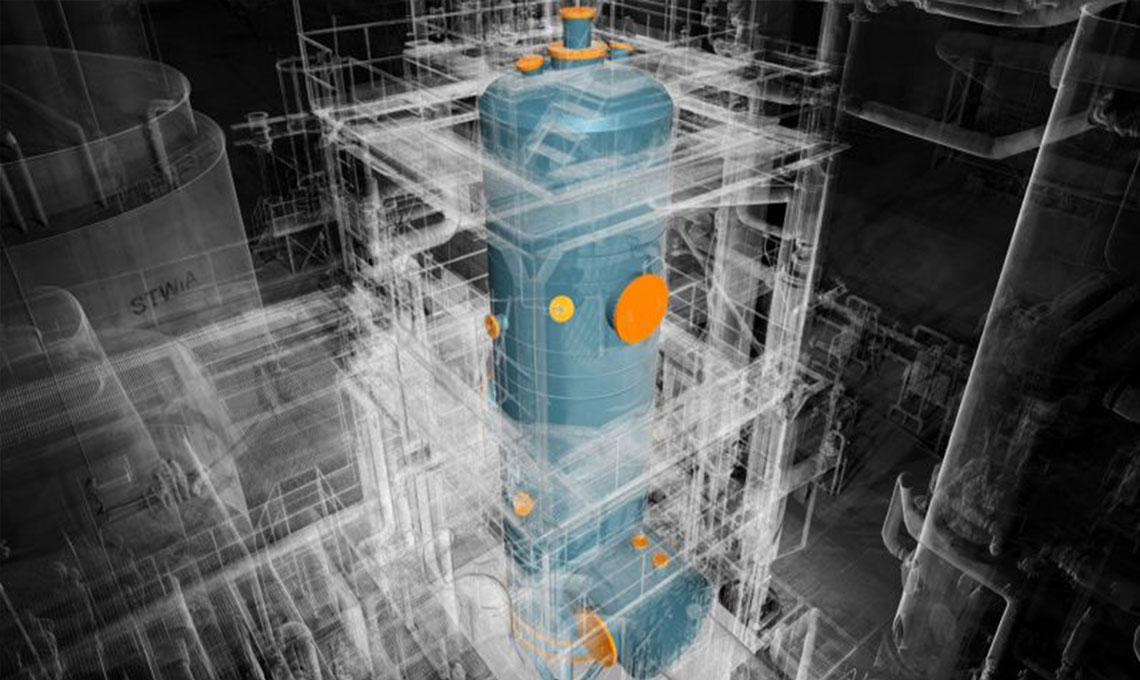

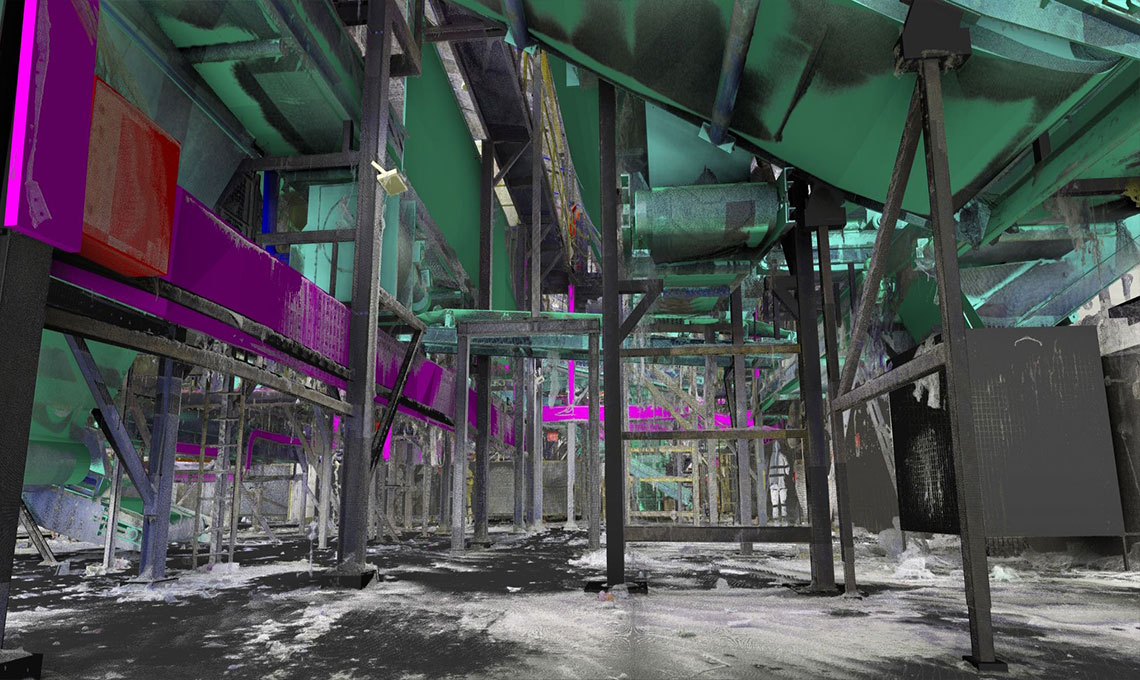

Process units also undergo many changes during operation for various reasons. Reconstructions, optimizations, regular and annual repairs, accidents, unwanted happenings, etc. impose inevitable changes on industrial sites. So, in a short time after the operation of the units, the validity and compliance of the archival documents in comparison with the situation of the first day of the complexes will gradually fade. Thus, the serious shortcomings and defects of the available archival maps on the one hand and the objective and physical changes of the exploitation areas over time on the other hand, make it more difficult for engineering designers who are in charge to tackle with projects related to these units. Creating an up-to-date 3D model of these units using laser scanning technology has been a unique and irreplaceable solution in recent years. Having an electronic twin model of an operating unit is a clear-cut case for all that an engineering or management design team needs in these units to advance its various industrial goals

RRE Company, with accurate knowledge of what are required by engineering designers in As-built projects stepped into laser scanning business. All staff have extensive and deep-rooted experience in the field of detail design of process units. Rubesh Co. has equipped with a wide range of hardware and software facilities in this regard. Rubesh has a long list of various projects in process units in Iran since 2009. In order to get a true picture of standard laser scanning services, we invite various employers and applicants of this technology especially fellow Iranians to consult with experts in this field before any action. It is highly recommended to use right hardware and software in related project. Since this is a new technology sometimes it turns to be confusing. Especially when it comes to a common name in the created files from Laser Scanners. Point Cloud data! It has to be said, each one of different laser scanning packages has been developed for specific purposes and couldn't be used instead of other. In short, the 3D point cloud model which is needed in the field of road construction projects has no place in the issues of oil, gas, architecture, etc., and also the product that is used as a point cloud in the process units required by detail designers has no connection with the as built models of road construction or environment models.

In order to clarify what you probably need in your 3D laser scanning project, contact us. We welcome our customers and offer them free consulting about our specific specialty. Rubesh Co. proudly answers all customers' engineering questions. What makes us most proud is that, as a privet enterprise we have opened up a groundbreaking and quite serious engineering establishment in our country. Which has been well located and developed with our ambitious and strict employees.