3D laser scanning technology

Early signs of Laser scanning technology has been emerged from early 1990s, when reverse engineering widely expanded. Industrial manufactures noticed it is a sort of short cut to get product's detail instead of spending a fortune for research and developments. Usage of early scanner was very limited. From one hand they were just available in laboratory conditions and on the other hand they were not that applicable for complicated physical shapes. Both issue absorbed all the researcher’s attentions for years.

Between 1990 up to 2000, all the reverse engineering efforts were concentrated over scanning small objects. Meanwhile researchers gradually had been facing with a new challenge. It was a hectic demand in the market for 3D laser scanning of big objects and even environment. In the beginning, market demands for environmental reverse engineering had been raised from ancient architectural monuments. Bridges, palaces, towers, these places had no kind of archive documents for their restoration. Therefor there were nothing to handle engineering actions except their facade. Although some methods were posed before 2000 for outdoor 3D mapping. But they were totally different from laser scanning methods. Those ideas were not much of a good engineering solution but were the only available one at its own time! As soon as laser scanning technology emerged from the horizon of science all attentions turned to that. It infused this idea that laser scanning is the one that market needs. Other methods were difficult to use and not economical. In less than a decade outdoor laser scanning obstacles had been resolved. New devices would have well-developed to 3D measurement in not only laboratory conditions but also in open area. Simultaneously 3D modeling software were improved widely and were capable to be uploaded by captured data from diverse scanners. Within 2000 prime generation of environmental laser scanners utilized in the mentioned projects and developed to capture modern architectural buildings as well.

Industrial operators and detail designers (in factories and refineries…) had a same problem in operating areas. Lack of archive information was a chronic problem for them. Operating area requires periodic maintenance. Operators normally have to deal with technical unexpected matters or renovation issues. This is why inevitable geometrical change happens in operational area while exploiting. As they get older, bigger and bigger changes appear from what it was at the first day. So credibility of existing documents gradually perishes. That time abundance of detail information in industrial plants were such a big deterrent for 3D laser scanning job. Not only customized hardware but also proper software definitely were needed in such a complicated area. A breakthrough happened short after 2000 some hardware providers offered their environmental laser scanning products in the market. One of them was “zf-laser” Company, Who was deeply concentrated over operational area.

Around 2006, "Z + F" Company presented new kind of environmental laser scanners for industrial area or any other places that contains many detail geometrical information. Equipped for outdoor climate condition and capable to capture more than a tens of million point per each survey. At the same time sophisticated software taskforce presented a new software for launching the captured point cloud data. Software's name was laser control. Both achievements have been continually developed over years.

Laser Scanners

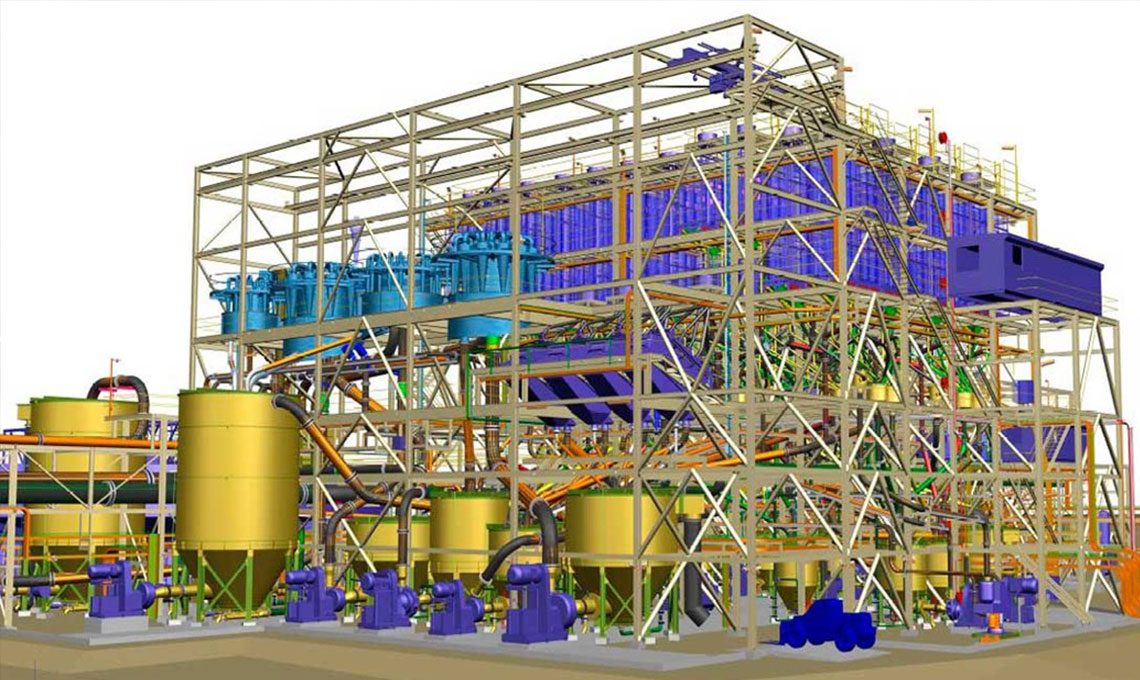

After 2006 construction industry has been one of early adopters for 3D laser scanning technology. It made a very big change. Especially in the projects that have been engaged with existing assets and operating areas. Ever before in such a projects, predicting spotless time tables and cost were very difficult stuff. Ever after, project's time schedules were drastically affected. Costs reduction appeared in different construction projects. The hardware, software and deliverables have all advanced, increasing their utility and decreasing the cost. Scanner improvements have made it possible for third parties to use different hardware and registration software, and experiment with more effective ways to get the job done. Ultimately, the evolution of the market has led to an explosion of options and efficiency. Developments such as “multi-stage, vector-based” registration algorithms, for example, have accelerated the processing of raw laser scanner data by 40%-80%, while removing manual steps.

These kinds of improvements massively reduce the cost of commissioning a scan — fueling a renaissance in laser scanner application and opening the door to the cost-effective use of laser scanners in any construction project. It is not bizarre these days that massive cost reduction happens in the shade of laser scanning technology. From authentic international construction companies continually 25% thrifty have reported in the massive projects. Nowadays new hardware and software around this subject made detail designer's dream come true. More than ever before.

Why Laser Scanning?

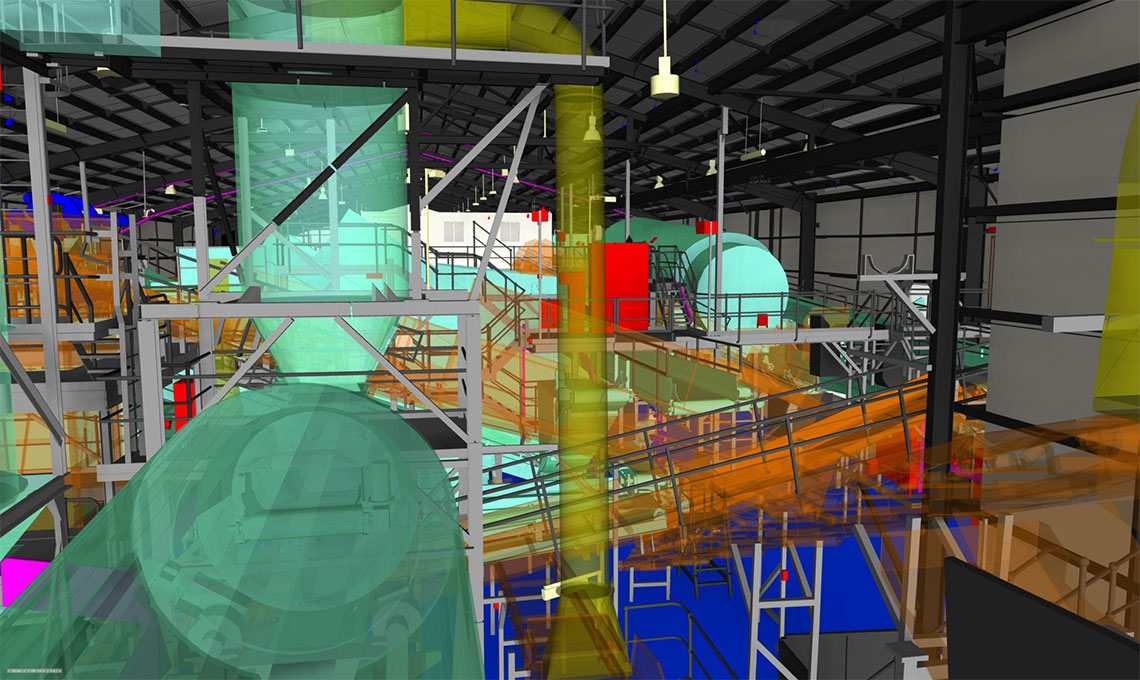

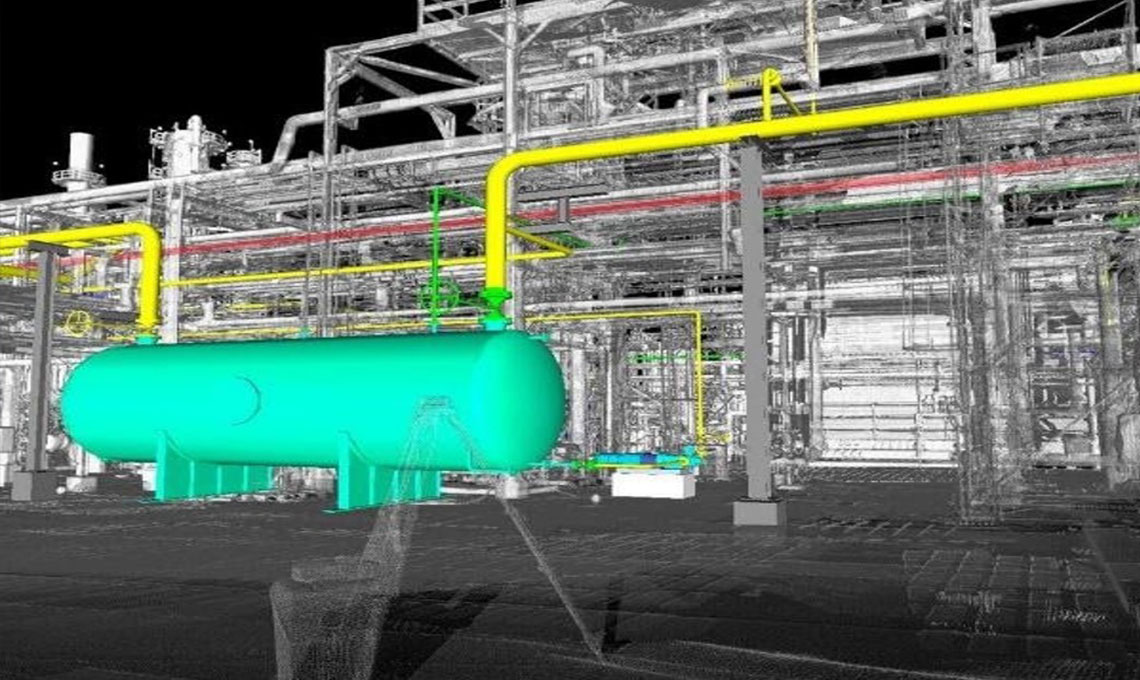

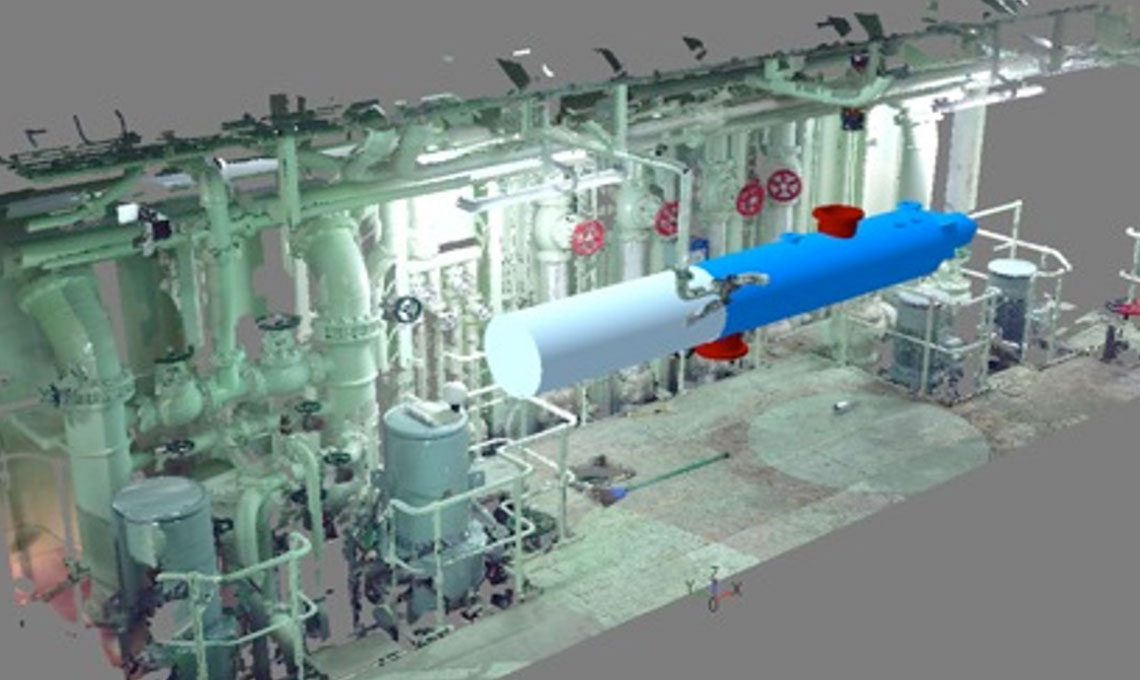

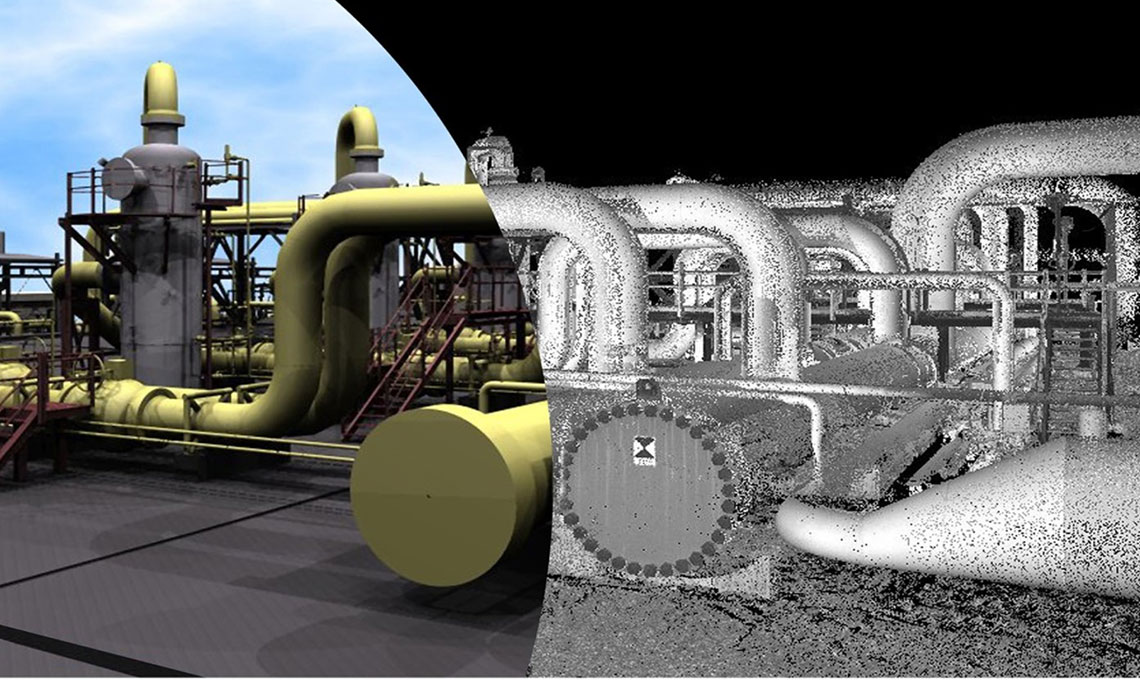

The value of laser scanning data to project planning mostly comes down to information capture. Laser scanners can be used to create accurate models from the very beginning, reducing the need to rework plans. The heightened level of accuracy reduces overhead cost, prevents delays and allows for more flexible planning and communication. This technology improves efficiency and reduces costly and time consuming mistakes. By utilizing this powerful technology, at first place users get point cloud data. Then they can create point cloud 3D model.

Typically, data capturing by 3D Laser scanners is not comparable with other methods. 3D Point cloud data’s quality, surveying speed, data’s accuracy are unprecedented and there is nothing similar ever before. Using 3D laser scanning create accurate 3D models which reflect the special relationship between elements of the objects.

Owners/Operators are now also well cognizant to the benefits of 3D laser scanning. Laser Scanning allows for compliance with health and safety regulation. Remote data capture is possible and less elevated work is required. EPC contractors continue to benefit from 3D Laser scanning practical data. Laser scanning data allows for the management of building data throughout its life cycle. It aids communication and collaboration between engineers, builders, and owners.

3D Laser Scanning advantages:

Authentic documentary evidences from international companies show that 3D laser scanning technology, has obviously made a positive impact over triangle of "cost, time and quality of work" in diverse industrial and architectural projects all over the world. In the projects with centralized management, the costs of a project are strictly monitored from the engineering phase to commissioning. By updating traditional methods and small shifts in the share of engineering costs, the use of 3D laser scanning technologies leads to an undeniable increase in the quality of work and heads on significant savings in the cost and time of projects. According to reliable reports from reputable international companies, this cost reduction will reach to 25% of the total project costs. Some of the technical and economic advantages of using 3D laser scanning and preparing As Built point cloud model in industrial complexes are as follows:

- Lower economic costs and incomparable quality and speed for gathering As-built situation in comparison with traditional methods. These advantages are not limited to engineering costs, and due to the possibility of accurate estimation for needed goods while construction, much more serious savings will appear in the purchasing required goods and project's take of material.

- Point Cloud 3D model has replaced with tens of thousands hardcopy drawings, user friendly working environment in related software, is a very important and up-to-date development in the engineering services. Using mentioned three-dimensional model, provides unbelievable access possibility for engineering studies in operational area through desktop. Comprehensive understanding inside operational area and unlimited possibility for any kind of measurements are available via computers. No need for the constant presence of experts at site.

- So running detail design engineering job and creating three-dimensional model based on the latest real site situation is possible. Captured data could be loaded on every kind of 3D modeling software. Then extracting any kind of as-built drawings is absolute pushover. List of consuming goods could be extracted easily from this up-to-date As Built 3D model. In some special cases like various engineering projects, optimization & renovation plans at site or unwanted accidents at site, this model is extremely important and provides valuable basic information to the designer.

- Recording accurate coordinate and dimensional data, provides special conditions for dismantling and re-installation industrial and process units, as well. It means that, 3D laser scanning creates a coherent engineering package in relocation projects. This will facilitate and expedites the system reinstallation process, leading to a significant reduction in project costs.

Due to its wide application in industrial and process units, this issue has been very welcomed by employers and reputable engineering companies in recent years. These days in the international arena this activity has been turned into an integral part of detail engineering services. This is a specific action which is included in macro EPC contracts and there is no doubt about the use of this technology in various industrial projects.