What is 3D modeling?

3D modeling refers to the process of creating a mathematical representation of a 3-dimensional object or shape. A wide number of 3D software are also used in constructing digital representation of mechanical models or parts before they are actually manufactured. This approach provides excellent opportunity for engineering services to construct the parts, assemble them, and observe their functionality before they are even exists. 3D modelling is also used in the field of Industrial Design, wherein products are 3D modeled before representing them to the clients.

3D models are now widely used in a variety of industries. Motion pictures, video games, architecture, construction, product development and medical, all these industries are using 3D models for visualizing, simulating and rendering graphic designs. 3D modeling in construction is widely gaining popularity due to the plethora of benefits it offers.

3D Modeling in construction

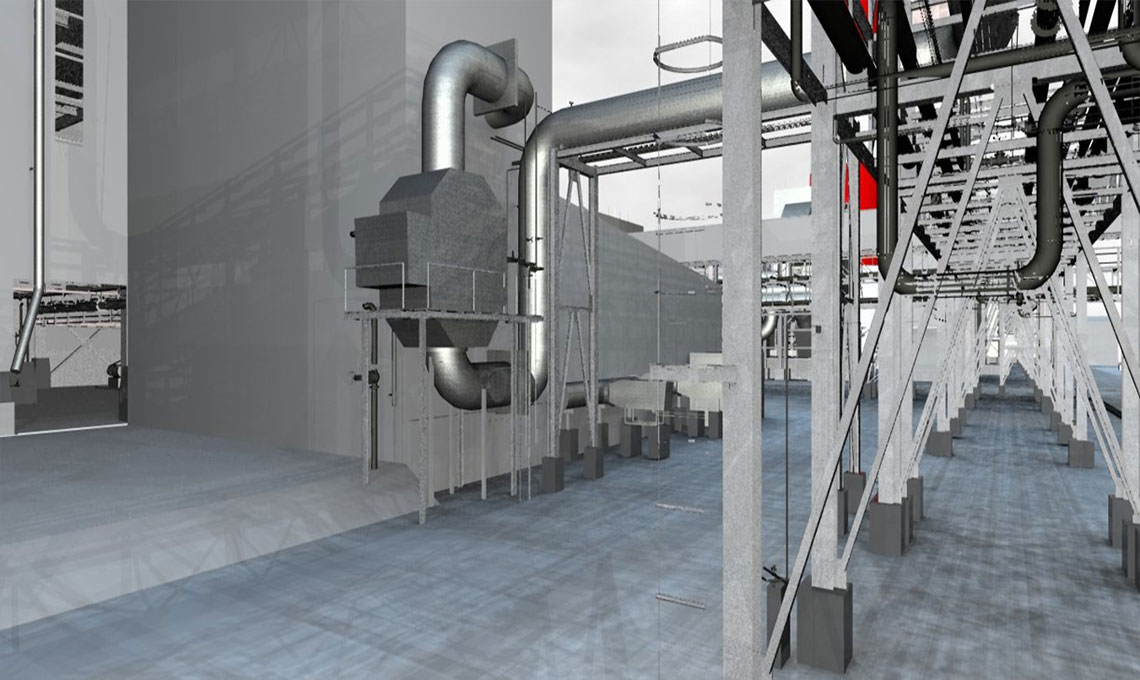

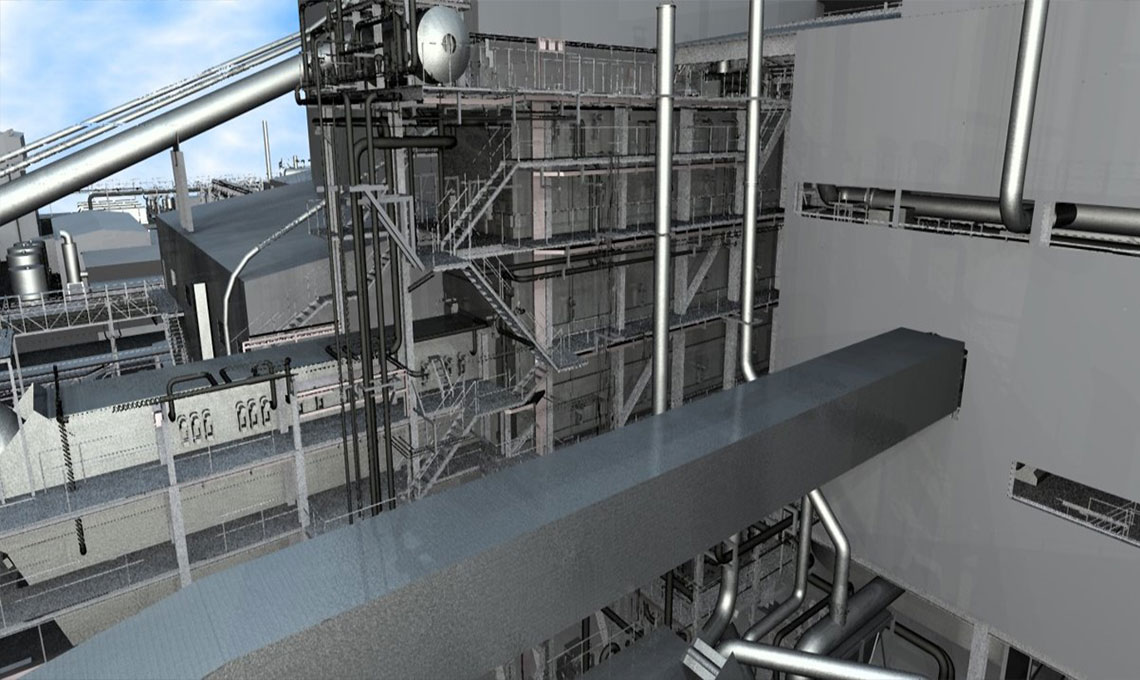

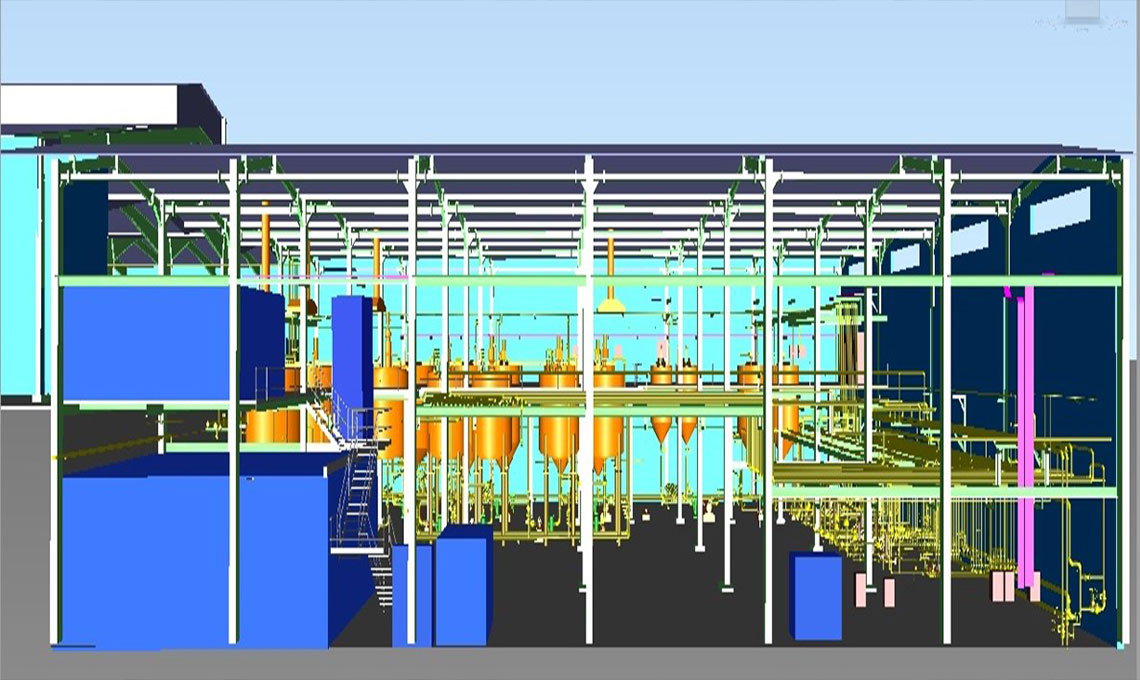

Technological advancements are making every task easier and better. We are now able to do more with less in almost every sphere of our lives. Every sector is riding the technology bandwagon for better outcomes and the construction industry follows suit. Be it BIM or 3D modeling, technology is enabling the construction industry to achieve more in lesser time with reduced cost. 3D modeling is changing the presentation world of architectural designs. 3D modeling is enabling architects and designers to be more creative and experimental. With technologies like reality modeling getting intrinsically weaved into the construction lifecycle, the construction process no longer involves rolling out blueprints of building designs. Construction has largely gone digital. Architectural presentations have moved from draft tables to desktops and tablets. The adoption of 3D modeling in construction has brought in numerous benefits. 3D or reality modeling, not only speeds up the design process but also enables architects and designers play around with different ideas and identify potential design problems before they become actual issues. 3D modeling in construction, by putting all the pieces together, provides a real-view of the finished project. Amazingly! 3D modeling brings a project to life without even moving a single speck of dust!

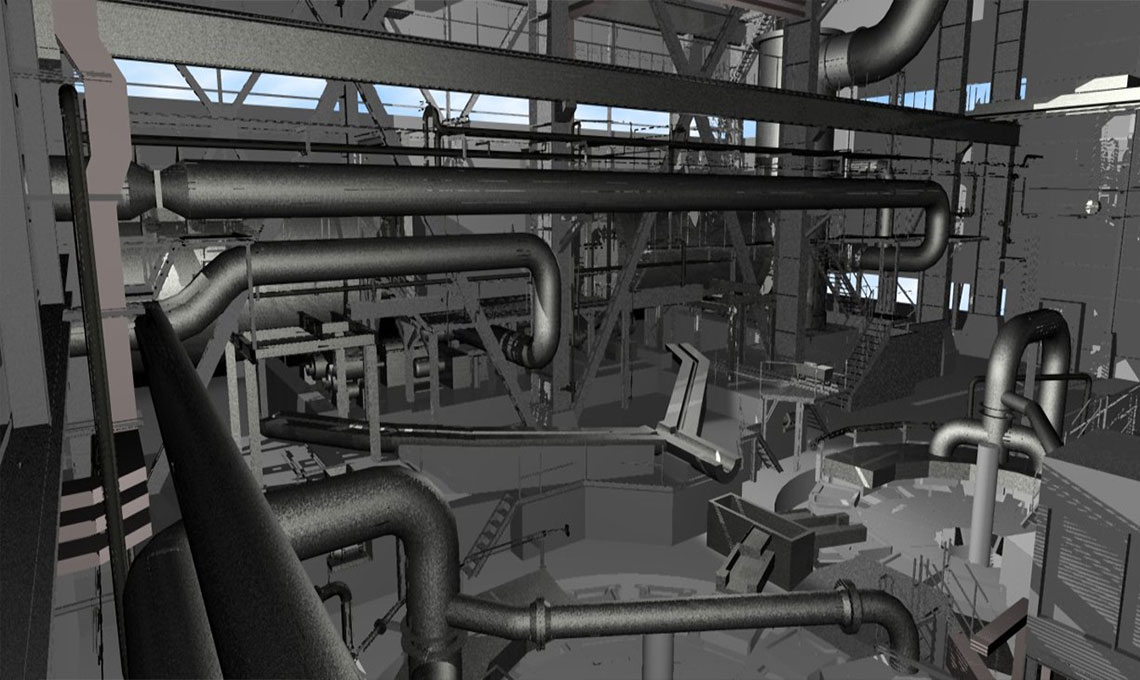

3D modeling in construction also allows animation. Naturally, the client can visualize so much more about an upcoming project that a flat drawing could ever provide. Clients can literally have a virtual walkthrough of the proposed building. Just like a 3D movie, a 3D model enables the client to get a feel of how things will be laid out. They can walk through the entry of their future asset, reach the every corner of their operation area and even visualize each part functionality. They can see all this even before a brick has been laid out! With 3D modeling, it also becomes easy to understand a structure in the context of the surrounding space. Transforming an open area to a factory with millions of technical detail information virtually surrounding it with lush landscaping is the power 3D modeling provides to an architect or designer. 3D architectural modeling provides a degree of realism that 2D images don’t. Using 3D modeling one can even considered needed material characteristics to buy along with texture of the tile that will be put up on a room’s floor. Interesting!

There is no doubt that use of 3D modeling in construction results in better designing and material utilization. 3D models can be rotated for different perspectives and gather additional views. The advantages of 3D modeling include;

- Checking the errors which might occur in the drawing process,

- Gaining better insight for surface patterns,

- Having virtual tours through walkthroughs,

- Getting renderings with customized interiors,

- Achieving more in lesser cost,

- Enhanced collaboration between teams involved in the construction process.

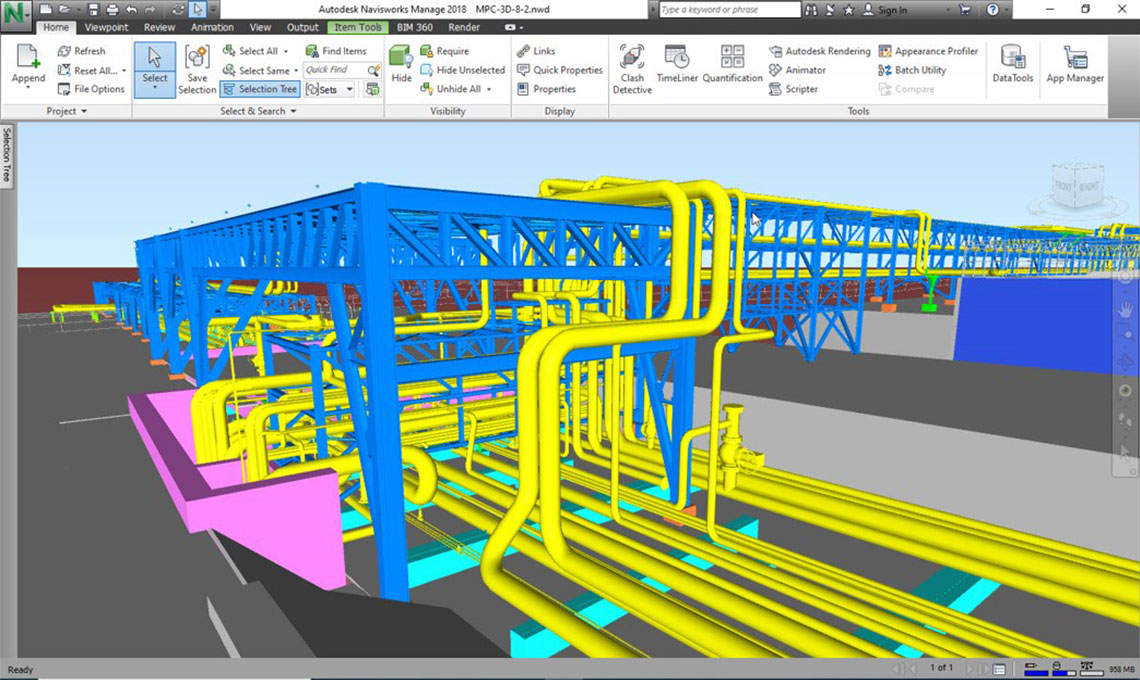

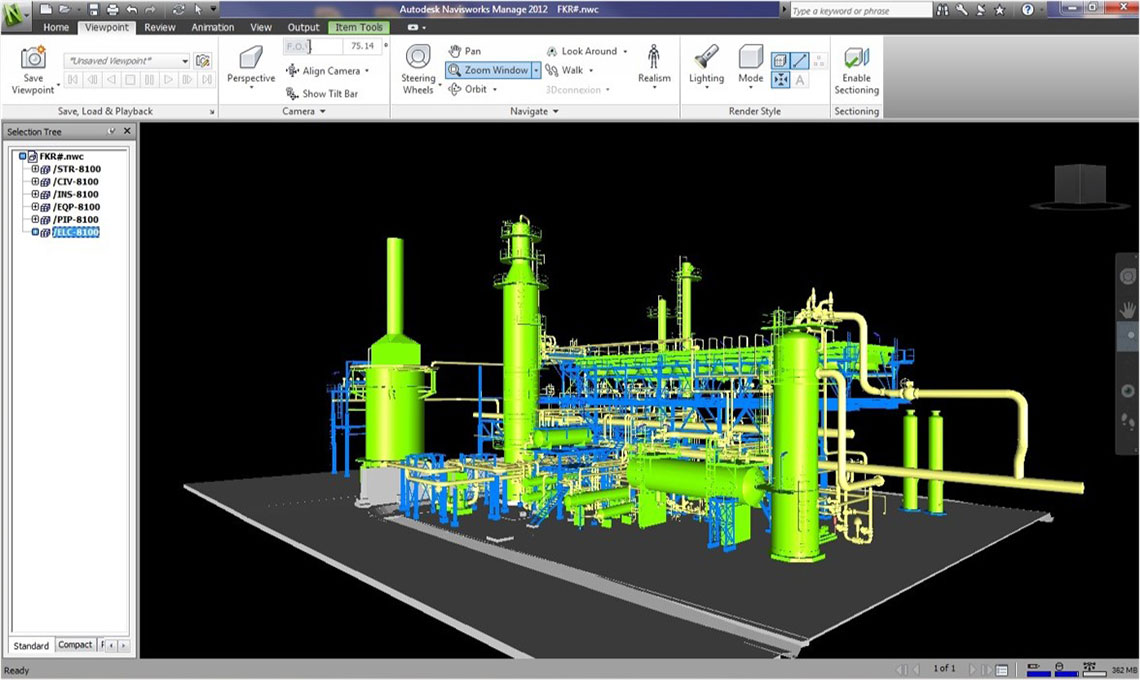

Software like PDMS, Bentley’s ... enables users to easily produce high-resolution 3D models of existing conditions for infrastructure projects of all types, derived from simple photographs. These highly detailed 3D reality meshes can be used to provide precise real-world context for design, construction and operation decisions for use throughout the lifecycle of an infrastructure project.

Electronic 3D Model / As Built 3D Model

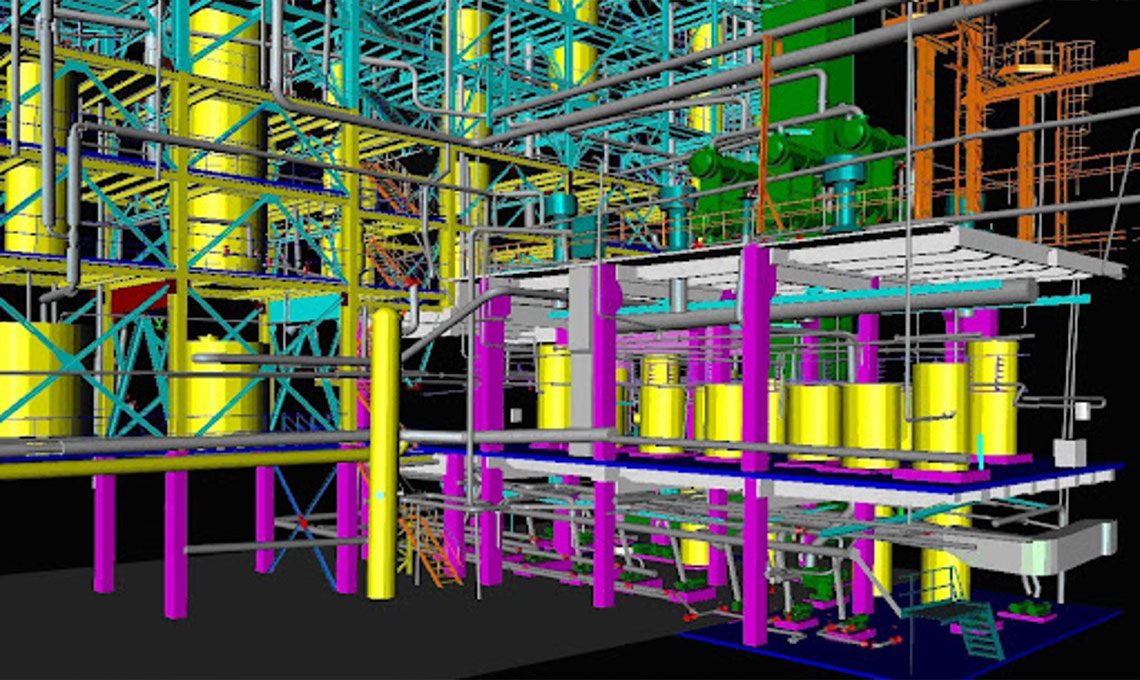

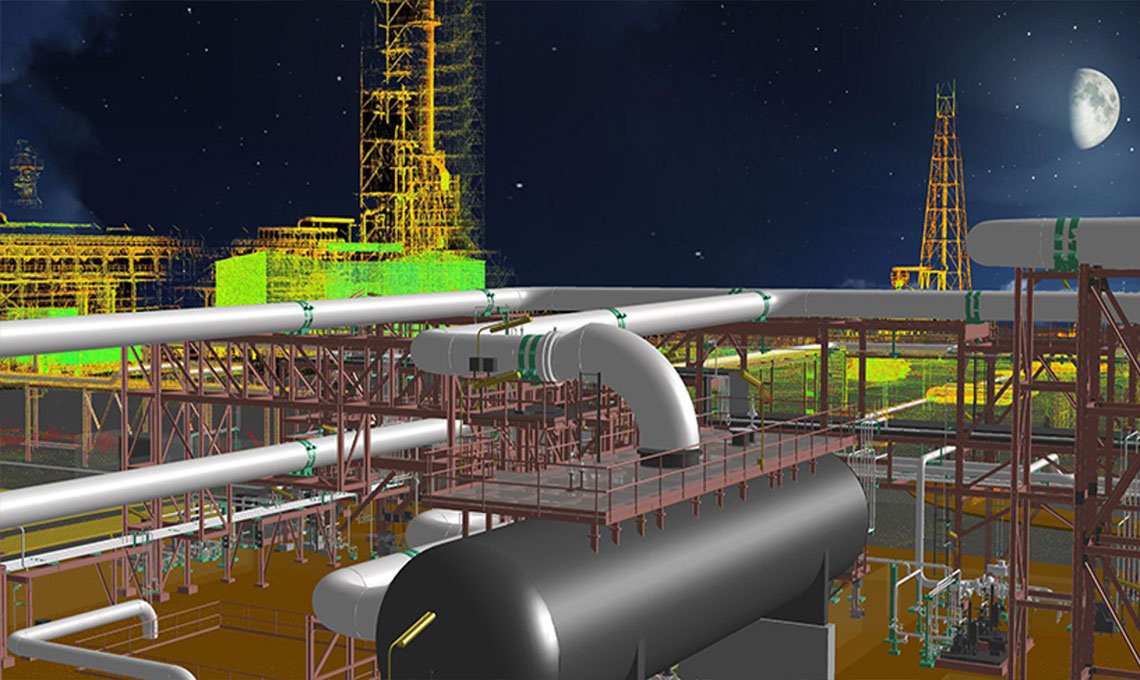

As-built 3D model is a developed 3D model which is made based on existing condition. It shows real erected situation at site. When As-built 3D point cloud model (or reality capture) creates from existing situation at site, in essence we get whole of the needed information that should be reflected in our “Issued for Construction” 3D model (IFC model). It could be applied for uploading inside IFC model.

After that, 3D model adjustment could be done easily. It means that level of detail and geometrical information in IFC model improves to be more real in comparison what it was before. It could be considered as a reverse engineering based on an existing pattern. As-built 3D model is a certain part of work in relocation or duplication projects. Regarding process units and factories. Where disassembling and reassembling or building typical units are required. Of course, in many different cases, this engineering services is also requested by client. Where the production of as built drawings or extracting list of used material in the workshop is on the agenda.

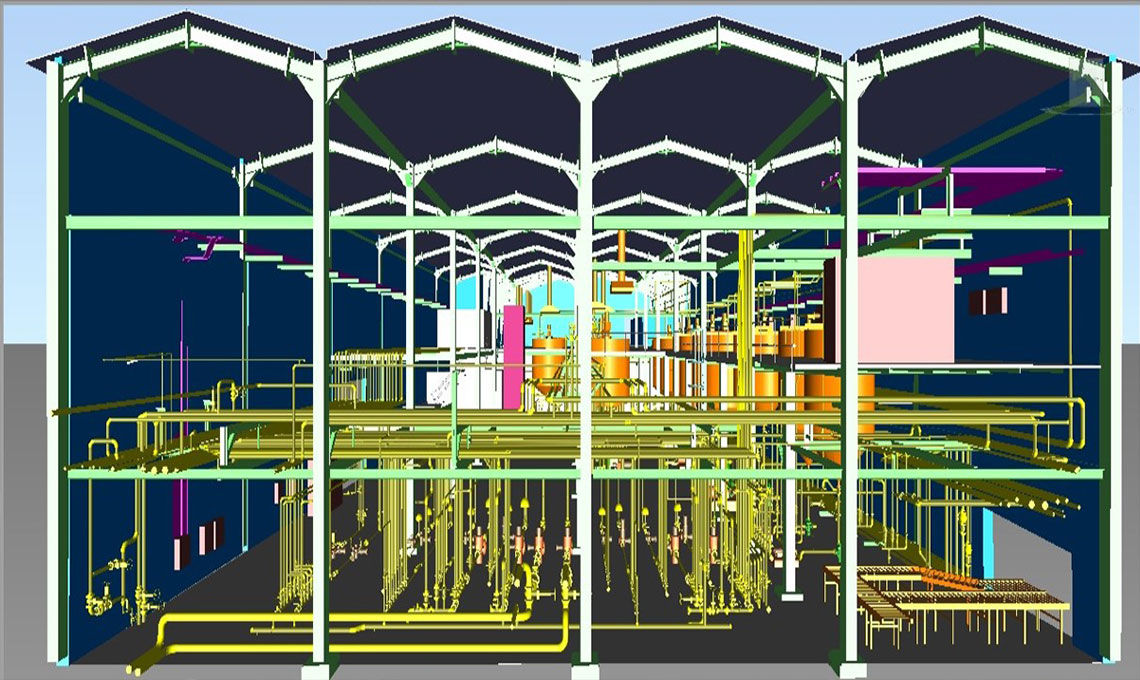

As-built 3D models would be used for specific designing propose too. When detail design engineers need to recalculate static and dynamic loads in those projects it is quite important. This issue is intended for employers to redesign systems. also creating the computerized intelligent as built 3D model and then generating as built drawings for engineering sections is important as well. Due to the high diversity of modeling software in different engineering field the process of building an as-built electronic 3D model is different from one to another. In operational areas 3D modeling job goes ahead based on PDMS or E3D software. But in architectural project mostly we have to deal with Revit and AutoCAD software. We are intended to give a brief explanation about as-built 3D modeling in mentioned topics.

3D Modeling of As-built conditions in PDMS and E3D software

Three-dimensional modeling of process units can be done in two primitive and intelligent levels. Primitive modeling leads toward two result. We can get through those models into geometrical information plus initial schematic drawings. The intelligent 3D model can be used to extract isometric drawings and piping plan, plot plan, take of material list (MTO) and so on.

One of two wings for getting intelligent model (in PDMS or E3D software) is the basic documents of the project. Including PMS and P&ID documents, mechanical data sheets, etc. The second wing is the As-built 3D point cloud model. Note that we could connect (Link) these models to computational and analytical software such as CAESAR, Pipe net. We can Line up and P&ID drawings, as well. Due to the time consuming construction of such a 3D model, this action is recommended where the employer has the requirements to extract such details.

Point Cloud 3D models could be uploaded in Revit software. Sometimes we have to deal with a building or a monument, that there is no enough supportive engineering information. Projects’ aims could be restoration plan or kind of renovation or development issue. No matter we don't have an enough supportive engineering documents or there is a huge shortage and we don't have even a single drawing.

Electronic As-built 3D model based on existing situation in the architectural asset can be built up. Provided that 3D Point Cloud model has already been created from site. Reverse engineering would be quite familiar pattern in such a project.